In leatherwork, various ways of making leather affect the product’s appearance and texture, such as shrinking. When you make shrunken bison leather, the process will require knowledge and skill to produce the best result, and once you have these tools, you will have an easier time enhancing it. Read on to learn how to process shrunken bison leather and learn another method of the trade to optimize your leather-making skills.

What Is Shrunken Leather?

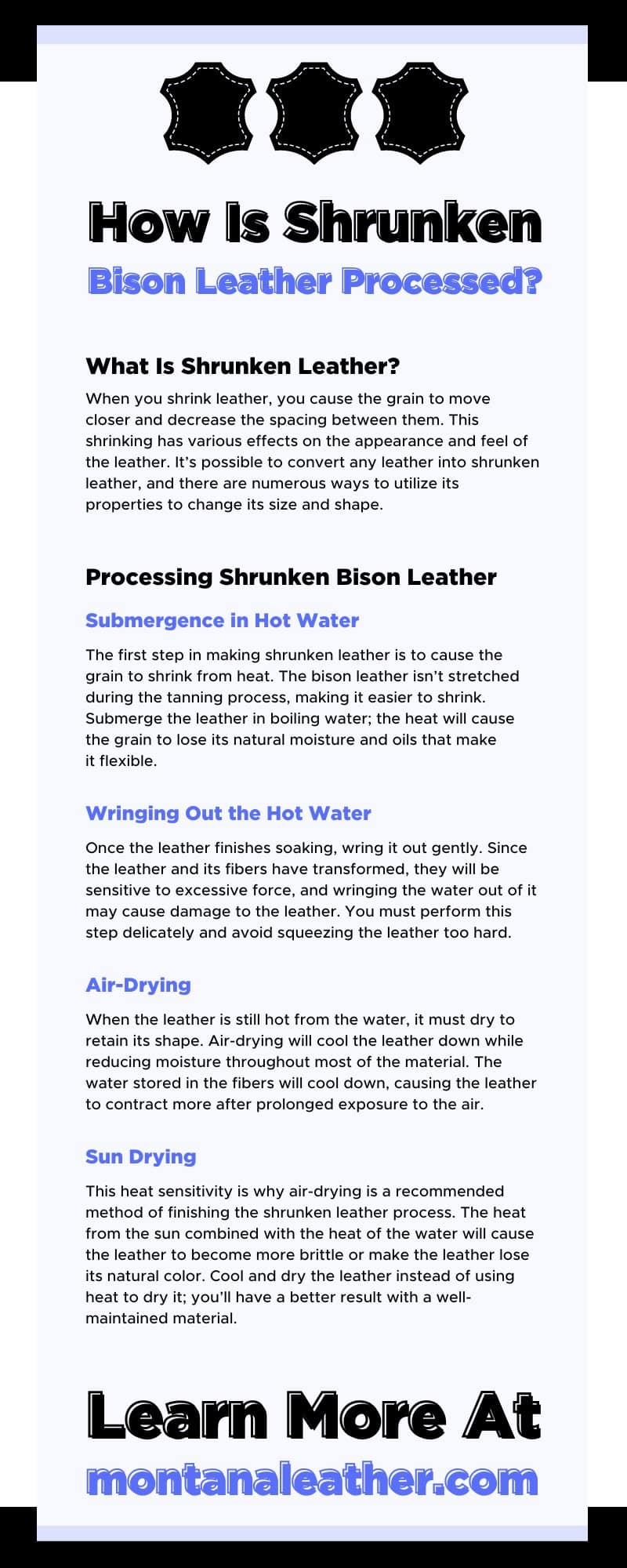

When you shrink leather, you cause the grain to move closer and decrease the spacing between them. This shrinking has various effects on the appearance and feel of the leather. It’s possible to convert any leather into shrunken leather, and there are numerous ways to utilize its properties to change its size and shape.

The Benefits of Shrunken Leather

Creating shrunken leather has numerous benefits, but it typically improves the durability and grain of the material. Shrunken leather is a popular product in fashion and winter gear because of its appearance and improvement in strength, which helps in harsh winters when a dense material is needed. The benefits of this leather may feel subtle but make a significant difference when wearing the leather or using it for crafting.

Better Durability

As the grain presses closer together, the leather becomes thicker because its surface is denser. Cold environments where thick jackets are necessary will become less brutal when you wear shrunken leather.

Even if the jacket isn’t thick, the tight grain and texture will block out the cold and trap heat. The tighter grain will also keep out moisture, making shrunken leather functional even in heavy rain or other precipitation. Durability is an essential part of leather and one of the primary focal points of leather making. Consider making shrunken leather for items crafted to handle the elements.

Detailed Grain

The effects of shrinking leather will cause the grain to change its shape and feeling. The grain tightens to decrease the space between each grain, but shrinking also raises the grains. The heightened bumps and patches in the grain will feel more defined in shrunken leather, and a leather clothing item will feel different on a person’s skin.

The raised grain has a unique aesthetic appearance that makes leather look more accentuated on an item. Use shrunken leather to improve the appearance of an item and make your leather crafting have great quality and appearance.

Shrunken Bison Leather

Previously, we mentioned that all leather could become shrunken leather, but it’s important to know that some leather, like bison leather, will make better shrunken leather. Bison leather already has various properties that make it a great material, such as being significantly stronger than cow leather and having larger pores for better breathability.

Since you don’t typically stretch this type of leather, it will have an easier time shrinking and improving the attributes that it already has. Shrunken bison leather will have a noticeably more rugged grain with raised bumps. The material will look tougher and more durable after the shrinking process, and many people will feel the material and appreciate how dense it is.

Processing Shrunken Bison Leather

The process of shrinking leather may seem challenging since you’ll need to use discretion and delicacy. But once you get the gist of how the process works, you’ll quickly have a knack for doing it.

There are a few ways that shrunken bison leather is processed, but there’s a particular method to let the leather’s natural properties cause it to shrink. Each step in this process will cause the leather to shrink and swell until you have an excellent piece of shrunken leather.

Submergence in Hot Water

The first step in making shrunken leather is to cause the grain to shrink from heat. The bison leather isn’t stretched during the tanning process, making it easier to shrink. Submerge the leather in boiling water; the heat will cause the grain to lose its natural moisture and oils that make it flexible.

This moisture loss causes the leather to shrink and brings the grain closer together. However, the presence of the water will also cause the leather fibers to swell, which will become an important part of shrinking the leather in a later step. Soak the leather for 15 to 30 minutes before moving to the next step.

Wringing Out the Hot Water

Once the leather finishes soaking, wring it out gently. Since the leather and its fibers have transformed, they will be sensitive to excessive force, and wringing the water out of it may cause damage to the leather. You must perform this step delicately and avoid squeezing the leather too hard.

You’ll still want a small amount of moisture left inside the fibers to give the shrunken leather the raised appearance that it’s known for. The moisture in the fibers will also play a role in the next step, causing the leather to shrink further.

Air-Drying

When the leather is still hot from the water, it must dry to retain its shape. Air-drying will cool the leather down while reducing moisture throughout most of the material. The water stored in the fibers will cool down, causing the leather to contract more after prolonged exposure to the air. Thanks to the swollen size and tighter spacing of the grain, the shrunken leather will now have a new appearance. People will love that appearance and want to buy your bison leather for sale.

Sun Drying

The heat from the sun is a great way to dry the leather after it’s finished soaking. However, leather is sensitive to heat in the prior steps, and limiting direct heat is important to avoid damage.

This heat sensitivity is why air-drying is a recommended method of finishing the shrunken leather process. The heat from the sun combined with the heat of the water will cause the leather to become more brittle or make the leather lose its natural color. Cool and dry the leather instead of using heat to dry it; you’ll have a better result with a well-maintained material.

Repeating the Process

Shrunken leather may expand back to its original size after you’ve worn it for some years. You’ll need to repeat the shrinking process to maintain the texture and density of the leather, but it’s possible to prolong the time before shrinking by protecting it from moisture.

The moisture will cause the leather to expand, and when combined with cooler temperatures, the whole process may come undone quickly. Keep your leather dry to help it maintain its condition. You’ll have less to worry about and more time to enjoy the material you’ve made.

Leatherwork has numerous aspects that involve the creation of a variety of leathers, and shrunken bison leather is one of the best you’ll find. Use this guide to understand the process of shrinking bison leather and how the material shrinks to enhance your craft and make better items.